Structural Design of Light Gauge Steel

Efficient Light Gauge Steel Design with Summit Engineering

Light gauge, or ‘cold-formed’ steel is most commonly used for wall, floor and roof framing. The material is increasing in popularity as an alternative for wood framing or heavy structural steel framing. Light gauge steel can be used in pre-fabricated panel sections as well as stick-built construction similar to light wood construction. It is competitive with wood in terms of cost and workability. However, it contains the strength and material properties of structural steel (non-combustible and strength). It has the additional benefit of being galvanized to prevent corrosion.

The International Building Code limits wood-framed construction to effectively 4-stories depending on project specifics. Cold-formed steel structures can go much higher. It is common to build 8 to 9-stories with light gauge up to 180-feet. Equally as important, the area limitations for light gauge are far greater than wood construction.

The staff at Summit Engineering is experienced with preparing cold-formed steel designs throughout New England, New York, New Jersey, Pennsylvania, Florida and the USVI. Our construction documents can be produced in a manner to avoid the shop drawing submittal process. Our drawings are the shop drawings!

Summit’s experience with light gauge steel design includes:

- Maplewood at Bethel Senior Living – Bethel, CT

- Vermont Public Health Laboratory, Colchester, VT

- Chelsea Fire Department, Chelsea, MA

- LA Fitness, Chestnut Hill, MA

- Ellis Hospital, Schenectady, NY

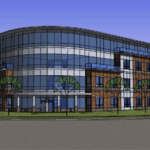

Summit provided the light gauge steel design and shop drawings for the new Maplewood at Bethel Senior Living Center in Bethel, CT. The structure uses light gauge steel bearing walls for the three-story load bearing structure. Our engineers at Summit designed the floor framing using multiple different joist sizes to create the most cost effective design.

Summit’s experience with light gauge steel design includes a variety of institutional and commercial structures. Our engineers are experienced in designing and producing shop drawings for light gauge steel projects. To learn more about the correct design of light gauge steel, please read Cold-Formed Steel Facade Framing written by Summit Engineering principle Anthony Coviello published in Structure Magazine.

Ready to speak with an

engineer about your project?

Contact Us Today

Related Topics

news

-

10.4

Read More

Read MoreSummit Fishing Outing 2021!

The Team had a blast on this year's staff fishing outing!

-

01.8

Read More

Read MoreSummit Engineering Wins National Award!

Summit Engineering was named as an award winner for the 2019 Excellence in Structural Engineering Awards given by the National Cou

-

11.13

Read More

Read MoreSummit Engineering Receives 2019 SENH Excellence in Structural Engineering Award.

Harbor Way Ship Sculpture, 121 Seaport Boulevard, Boston, MA BACKGROUND In May of 2016 a portion of a ship’s hull was disco

-

11.10

Read More

Read MoreSummit Engineering Receives 2018 SENH Excellence in Structural Engineering Award.

Summit Engineering receives 2018 Structural Engineers of New Hampshire Excellence in Structural Engineering Award in the building

-

09.1

Read More

Read MoreSummit Engineering Receives 2017 SENH Excellence in Structural Engineering Award.

Northeastern University – Interdisciplinary Science & Engineering Complex - Spiral Stair Summit Engineering was contracte

-

05.20

Read More

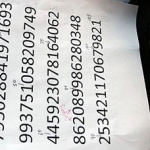

Read MoreSchool Board Honors Pi Day Winners

On May 12th, the Portsmouth School Board honored the Pi Day contest winners in the third, fourth, and fifth grades at each of the

-

04.30

Read More

Read MoreSummit Attends National Structural Engineering Event in Boston, MA

Summit Engineering was well represented at a recent national engineering event known as The 2014 Structures Congress held in Bosto

-

04.21

Read More

Read MoreWinners of NH Structural Engineering Firm’s Student Pi-Day Competition Shine at City Hall

The local school board earlier this month honored a handful of students who competed in and won a one-of-a-kind educational event

-

04.23

Read More

Read MoreJournal of Light Construction: Interview

Summit Principal Tony Coviello was interviewed this week for the Journal of Light Construction. In the article, Coviello

-

02.27

Read More

Read MorePortsmouth, NH Structural Engineering Firm, Headed to New Jersey to Assess Damage from Hurricane Sandy

Structural engineering staff from Summit Engineering in Portsmouth, NH traveled to the Jersey Shore this month, where they joined

blog

-

11.12

Read More

Read MoreIs Your Snow-filled Roof at Risk of Collapse?

Robert Champagne, principal of Summit Engineering, says that the best way to prevent a roof collapse from snow is to be proactive.

-

11.12

Read More

Read MoreRain on Snow: A Recipe for Disaster

Structural Engineers Explain Roof Load Dangers Structural Engineers at Summit Engineering, are cautioning homeowners throughout Ne

-

07.31

Read More

Read MoreTop Engineering Firm Names 11 Redevelopment Opportunities in Portsmouth

NH Engineering Firm Finds Redevelopment Potential All Over Portsmouth As one of the local engineering companies in th

-

07.15

Read More

Read MoreTop 5 Most Exciting Development Projects on The Rise In New Hampshire

Developers all throughout New Hampshire are bringing forth various dynamic development opportunities complete with quality archite

-

05.8

Read More

Read MoreThe Importance of Roof Inspection: Evaluating the Roof Envelope in Existing Buildings

At Summit Engineering, besides typical Structural Engineering, we also find ourselves investigating problems in existing building

-

12.2

Read More

Read MoreBrick Engineering 101 – Part 1

Brick Engineering - Common Challenges and How To Fix Them. Brick masonry is a ubiquitous building material—it has been around f

-

08.27

Read More

Read MoreNH Flood Zone Designations FAQs

What To Know When Building in Flood Insurance Zones The recent release of preliminary Flood Insurance Rate Maps (FIRMs) by the Fe

-

07.18

Read More

Read MoreBuilding in Flood Insurance Zones: What to Know About Coastal Zone Engineering

The Federal Emergency Management Agency (FEMA) recently released the preliminary Flood Insurance Rate Maps (FIRMs) for the Seacoa

-

07.9

Read More

Read MoreTop 11 Most Important Historical Building Structural Renovations in NH

As one of the original 13 states, New Hampshire most certainly has its fair share of historic property. From the working waterfro

-

04.23

Read More

Read MoreHistoric Building Preservation: What to Know About Historic Tax Credits

Examples of historic building preservation are all around us — especially in a place as historically rich as New England